Gravity Casting: Process, Advantages, and Applications

The Gravity Casting Process

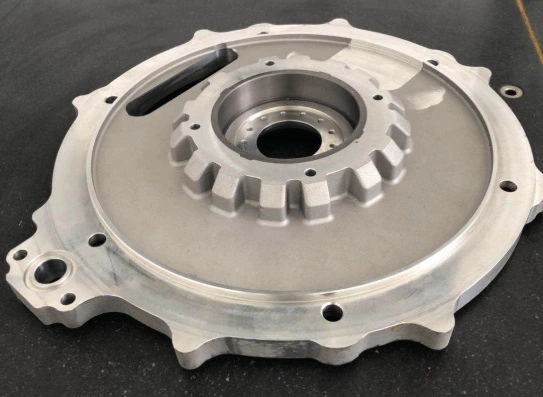

Gravity casting is a fundamental metalworking technique that leverages gravitational force to shape molten metal. The process involves carefully pouring liquefied metal into a mold cavity constructed from materials like sand, metal, or ceramics. As the molten metal descends naturally, it fills the entire mold cavity, gradually solidifying and adopting the precise geometric configuration of the mold. This straightforward method represents an efficient manufacturing approach, particularly suited for producing large-scale, structurally uncomplicated components. The gravitational flow ensures consistent metal distribution, minimizing turbulence and potential defects during casting. Manufacturers appreciate this method's simplicity and reliability, making it a cornerstone technique in metal component production across various industrial sectors.

Advantages of Gravity Casting

Gravity casting presents numerous strategic advantages for manufacturing operations. Its cost-effectiveness becomes particularly pronounced during large-scale production runs, where economies of scale significantly reduce per-unit manufacturing expenses. The process demonstrates remarkable versatility, accommodating a broad spectrum of metals and alloys with consistent performance. Manufacturers benefit from minimal equipment requirements, translating to lower initial capital investments compared to more complex casting methodologies. The technique excels in producing substantial, heavy castings with excellent dimensional accuracy and structural integrity. Reduced complexity translates to streamlined production processes, shorter setup times, and enhanced operational efficiency. These inherent advantages make gravity casting an attractive option for industries seeking reliable, economical metal component manufacturing solutions.

Applications of Gravity Casting

Gravity casting's versatility enables its widespread adoption across diverse industrial domains. In the automotive sector, manufacturers utilize this technique to produce critical components like engine blocks, cylinder heads, and transmission housings, where structural reliability is paramount. Aerospace engineers leverage gravity casting for manufacturing intricate turbine blades and complex structural elements that demand precise geometrical configurations and high-performance materials. Construction and heavy machinery industries rely on this method to create large, robust machinery parts and equipment components capable of withstanding significant mechanical stress. The oil and gas sector implements gravity casting for producing essential infrastructure elements like valves, pumps, and pipeline fittings that require exceptional durability and precision. General machinery manufacturing extensively employs this technique for creating gearboxes, structural housings, and mechanical components, demonstrating the process's adaptability across multiple engineering disciplines.

Low Pressure Casting: Process, Advantages, and Applications

The Low Pressure Casting Process

Low pressure casting is a more advanced method that uses controlled pressure to force molten metal into a mold cavity. In this process, the molten metal is held in a pressurized furnace below the mold. As pressure is applied, the metal is pushed upwards through a feed tube into the mold cavity. This controlled filling process allows for better regulation of the metal flow and solidification, resulting in improved casting quality and consistency.

Advantages of Low Pressure Casting

Low pressure casting offers several advantages over traditional gravity casting:

- Enhanced control over the filling and solidification process

- Improved casting quality with fewer defects

- Better yield and reduced material waste

- Ability to produce complex, thin-walled components

- Excellent surface finish and dimensional accuracy

- Reduced porosity and improved mechanical properties

Applications of Low Pressure Casting

Low pressure casting is particularly well-suited for applications that require high-quality, complex castings:

- Automotive: alloy wheels, engine components, and structural parts

- Aerospace: turbine blades, compressor housings, and structural components

- Medical equipment: implants and surgical instruments

- New energy equipment: solar panel frames and wind turbine components

- Consumer goods: high-end cookware and decorative items

Choosing Between Gravity Casting and Low Pressure Casting

Factors to Consider

When deciding between gravity casting and low pressure casting, several factors should be taken into account:

- Part complexity and geometry

- Production volume requirements

- Material properties and specifications

- Surface finish and dimensional accuracy needs

- Cost considerations and budget constraints

- Available equipment and expertise

When to Choose Gravity Casting

Gravity casting may be the preferred option in the following scenarios:

- Large, simple shapes with thick walls

- High-volume production of uncomplicated parts

- Limited budget for initial equipment investment

- Production of heavy castings exceeding several hundred kilograms

- Applications where minor porosity or surface imperfections are acceptable

When to Choose Low Pressure Casting

Low pressure casting is often the better choice when:

- Producing complex, thin-walled components

- High-quality surface finish and dimensional accuracy are required

- Reducing material waste and improving yield is a priority

- Casting aluminum alloys or other lightweight metals

- Manufacturing parts for critical applications in aerospace or medical industries

In conclusion, both gravity casting and low pressure casting have their unique advantages and applications in various industries. The choice between these two methods depends on the specific requirements of the project, including part complexity, production volume, quality standards, and cost considerations. For manufacturers in the oil and gas, metallurgical and mining machinery, construction, aerospace, and automobile industries, understanding the differences between these casting processes is crucial for making informed decisions and optimizing production processes.

At China Welong, we specialize in various casting techniques, including gravity casting and low pressure casting. Our experienced engineers and state-of-the-art facilities enable us to provide high-quality custom metal parts tailored to your specific needs. Whether you require gravity cast components for large machinery or precision low pressure castings for aerospace applications, we have the expertise to deliver exceptional results. To learn more about our casting capabilities and how we can support your manufacturing needs, please don't hesitate to contact us at info@welongpost.com.