Key Components for Automated Furnace Roll Systems

Advanced Sensor Technology

Incorporating cutting-edge sensors is paramount for the successful integration of furnace rolls into automated systems. These sensors serve as the eyes and ears of the system, continuously monitoring critical parameters such as temperature, roll speed, and material position. High-temperature resistant thermocouples and pyrometers are essential for accurate temperature readings, while advanced optical sensors can track the movement and positioning of materials on the rolls. Proximity sensors and encoders work in tandem to ensure precise roll rotation and alignment, crucial for maintaining product quality and preventing jams or misalignments.

Robust Control Systems

At the heart of an automated furnace roll system lies a sophisticated control system. Programmable Logic Controllers (PLCs) or Distributed Control Systems (DCS) form the backbone of these setups, orchestrating the intricate dance of roll movements, temperature adjustments, and material flow. These systems integrate data from various sensors and execute complex algorithms to maintain optimal furnace conditions. Advanced control software enables real-time adjustments, ensuring that the furnace rolls respond dynamically to changing process requirements or material properties.

Specialized Actuators and Drive Systems

The physical movement of furnace rolls in an automated system requires specialized actuators and drive systems designed to withstand high temperatures and harsh environments. Servo motors with high-temperature lubricants and cooling systems are often employed to provide precise control over roll rotation speed and direction. Hydraulic or pneumatic systems may be used for larger rolls or in applications requiring significant force. These drive systems must be carefully designed to ensure smooth, consistent operation while maintaining the ability to make fine adjustments as dictated by the control system.

Integration Strategies for Automated Furnace Roll Systems

Seamless Communication Protocols

Effective integration of furnace rolls into automated systems hinges on robust communication protocols. Industrial Ethernet protocols such as EtherNet/IP, Profinet, or Modbus TCP/IP are commonly used to ensure fast, reliable data exchange between the furnace roll control system and other components of the automation network. These protocols allow for real-time data sharing, enabling quick responses to process changes and facilitating comprehensive data collection for analysis and optimization.

Human-Machine Interface (HMI) Design

A well-designed Human-Machine Interface is crucial for operators to monitor and interact with the automated furnace roll system. Modern HMIs feature intuitive touchscreen displays that provide real-time visualizations of furnace conditions, roll status, and material flow. They allow operators to make adjustments, respond to alerts, and access historical data. Advanced HMIs may incorporate augmented reality features, enabling operators to visualize complex system dynamics or troubleshoot issues more effectively.

Data Analytics and Machine Learning Integration

To maximize the benefits of automation, integrating data analytics and machine learning capabilities into furnace roll systems is becoming increasingly common. These technologies enable predictive maintenance by analyzing patterns in sensor data to forecast potential equipment failures before they occur. Machine learning algorithms can optimize furnace roll parameters in real-time, adjusting to variations in material properties or environmental conditions to maintain peak efficiency and product quality. This level of integration transforms the furnace roll system from a mere automated process to an intelligent, self-optimizing component of the manufacturing ecosystem.

Challenges and Considerations in Automating Furnace Roll Systems

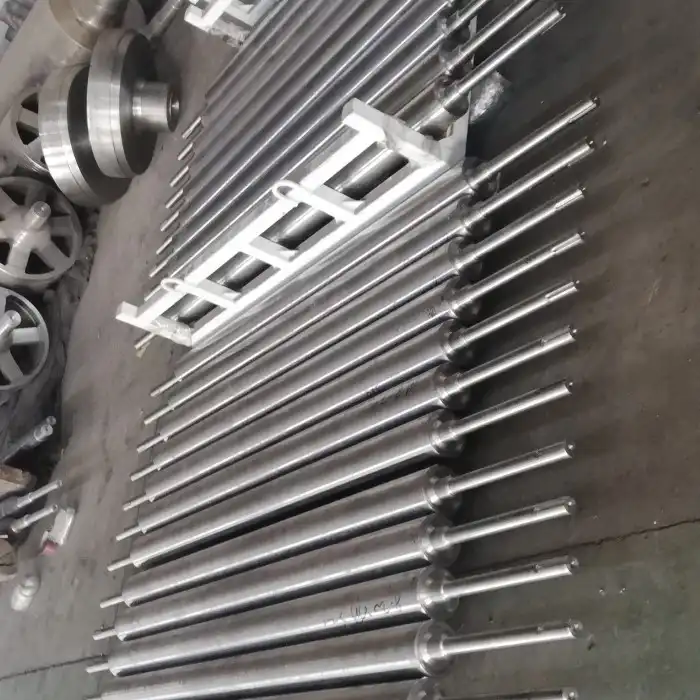

Material Selection and Thermal Management

One of the primary challenges in automating furnace roll systems is selecting materials that can withstand extreme temperatures while maintaining their mechanical properties. Advanced alloys and ceramics are often employed for roll construction, but these materials must also be compatible with the automated control and sensing systems. Thermal management is critical, not just for the rolls themselves but also for the associated electronics and sensors. Innovative cooling systems and thermal isolation techniques are essential to ensure the longevity and reliability of the automated components in high-temperature environments.

System Reliability and Redundancy

Given the critical nature of furnace operations in many industries, automated furnace roll systems must be designed with high reliability and redundancy in mind. This involves implementing fail-safe mechanisms, backup systems, and redundant sensors to ensure continuous operation even in the event of component failures. Regular maintenance schedules and condition monitoring systems are crucial to prevent unexpected downtime. Additionally, the system should be designed to gracefully degrade in case of partial failures, allowing for continued operation at reduced capacity rather than complete shutdowns.

Integration with Existing Infrastructure

Retrofitting existing furnaces with automated roll systems presents unique challenges. The integration must be carefully planned to minimize disruption to ongoing operations and to ensure compatibility with existing equipment and control systems. This often requires a phased approach, where automation is introduced incrementally, allowing for testing and optimization at each stage. Careful consideration must be given to the interface between new automated systems and legacy equipment, potentially necessitating the development of custom middleware or communication bridges.

In conclusion, the integration of furnace rolls into automated systems represents a significant leap forward in industrial process efficiency and control. By carefully addressing the key components, integration strategies, and challenges discussed, industries can harness the full potential of automated furnace roll systems to drive productivity, enhance product quality, and improve operational safety. As technology continues to evolve, we can expect even more sophisticated and intelligent furnace roll automation solutions to emerge, further revolutionizing high-temperature industrial processes. For more information on cutting-edge furnace roll solutions and automation technologies, please contact us at info@welongpost.com.